Material flow planning

Find out how you can optimize your production processes and save costs with systematic material flow planning in accordance with VDI 2498. We at Bross Consulting are your experts for logistics planning and material flow optimization. Contact us now for a customized offer.

What is material flow planning?

Material flow planning is a company-wide project that aims to design and optimize the material flow in a production plant. The material flow includes all movements of raw materials, semi-finished and finished products as well as auxiliary and operating materials within and between the individual operating areas. Efficient material flow planning can increase a company’s profitability, quality, flexibility and customer satisfaction. Material flow planning is based on the VDI 2498 guideline, which specifies a systematic and methodical approach for planning and optimizing material flow systems. The guideline describes the procedure, the use cases, the planning stages and the planning content of material flow planning.

Why is material flow planning important?

You can achieve the following benefits with material flow planning:

- They reduce throughput times, inventories, transportation routes and transport costs.

- They increase the capacity utilization, productivity, quality and flexibility of production facilities.

- They improve working conditions, ergonomics, safety and environmental protection.

- They enable the company to adapt to changing conditions, such as new products, increasing demand, market changes or technological innovations.

When does material flow planning make sense?

Planning the material flow makes sense if one or more of the following scenarios exist:

- Optimization of an existing material flow system: If the performance of an existing system is no longer sufficient, material flow planning can help to eliminate bottlenecks, waste or errors and increase efficiency.

- Expansion of an existing material flow system: If the company grows or changes, material flow planning can help to adapt and expand the existing system to the new requirements.

- Material flow planning for new projects: When planning a new production building or a new production line, material flow planning can help to design the optimum layout and technology for the material flow.

How does material flow planning work?

Material flow planning takes place in four planning stages according to VDI 2498:

Rough planning

The basic objectives, boundary conditions and solution variants for material flow planning are defined in the rough planning stage. The production program, process organization, space requirements and layout are taken into account. Rough planning provides an initial overview of the material flow relationships between the company divisions.

Ideal planning

In ideal planning, the best technical and organizational solution for the material flow is designed without taking into account economic or spatial restrictions. Ideal planning serves as a reference for the subsequent planning stages.

Real planning

In real planning, the solution variants from the ideal planning are adapted to the real conditions. The costs, economic efficiency, feasibility and risks of the different variants are analyzed and compared. Real planning provides the final selection of the preferred solution for the material flow.

Detailed planning

In the detailed planning phase, the selected solution from the real planning is worked out in detail. The work packages, the interfaces, the dimensions, the technical equipment, the structural and official requirements and the implementation of the new system are defined. The detailed planning provides the basis for the implementation of the material flow planning.

How can you carry out material flow planning?

If you want to carry out material flow planning, you can follow the steps below:

- Define the reason, scope, objectives and boundary conditions of your material flow planning.

- Collect the relevant data and information about your existing or planned production processes, products, resources, areas and material flows.

- Create a rough plan in which you outline and evaluate the basic solution variants for the material flow.

- Create an ideal plan in which you design the best solution for the material flow without taking restrictions into account.

- Create a real plan in which you adapt the solution variants from the ideal plan to the real conditions and compare them.

- Create a detailed plan in which you work out all the details of the selected solution from the real planning.

- Implement material flow planning by defining and implementing the necessary measures, resources, deadlines and controls.

- Check the results and effectiveness of your material flow planning by measuring and documenting the improvements achieved.

How can we help you?

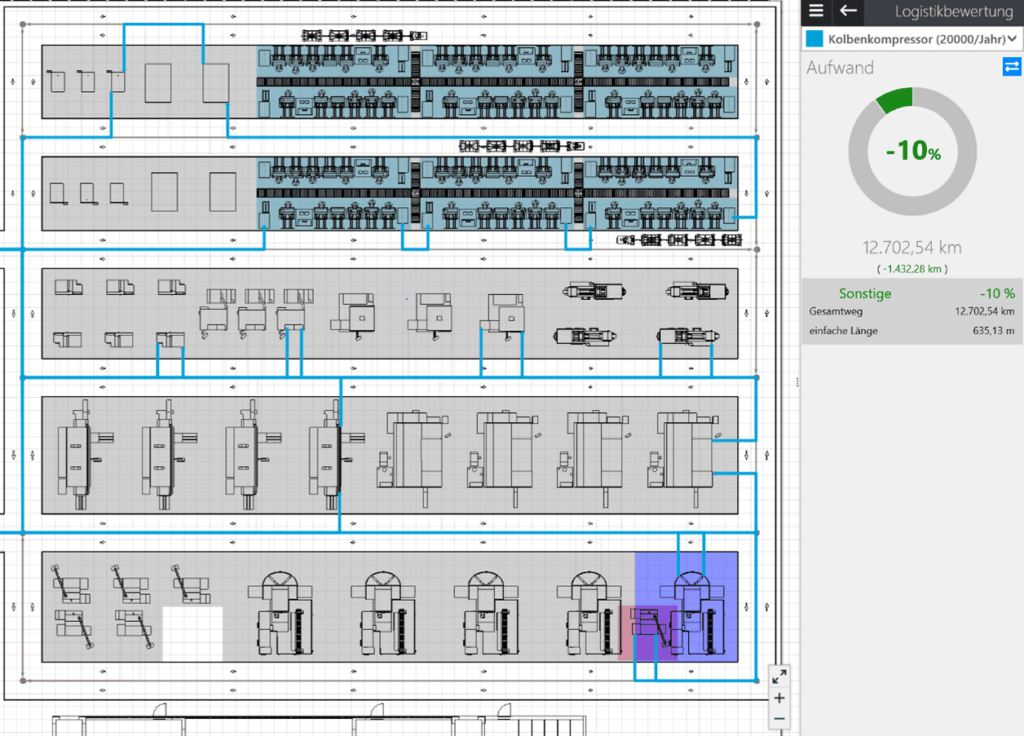

If you need professional support with your material flow planning, you’ve come to the right place. We at Bross Consulting are your technical management consultancy specializing in logistics planning and the optimization of your production and logistics systems. We have many years of experience and expertise in material flow planning in accordance with VDI 2498 and can help you to find the best possible solution for your individual requirements. We use modern material flow simulation software to virtually map your material flows and analyze them as part of a material flow analysis. We operate internationally and offer you a comprehensive service from the conception to the implementation of your material flow planning. If you are interested in an offer or have any further questions, please do not hesitate to contact us. We look forward to hearing from you.