CIP – Continuous improvement process

CIP, Continuous Improvement Process or Kaizen (from the Japanese: KAI = change; ZEN = the good), refers to the replacement of the good with the better. This is based on practiced, constant, continuous improvement measures that increase process, product and service quality in small steps, as required by ISO9001 in quality management, for example. In Kaizen, all employees are involved (especially executive levels) and enabled through training to recognize problems and develop their own detailed solutions (small steps), which are then implemented promptly. This leads to a cultural change in the company. Kaizen is based on standardized processes, order and cleanliness, visual management and an existing company suggestion scheme and develops its own company “attitude to life” or “working atmosphere” from these elements through their consistent and permanent application.

What are the prerequisites for CIP?

- The entire management must be committed to the CIP and fully support employees in its implementation

- Short and comprehensible decision-making processes must enable CIP proposals to be implemented promptly (sense of achievement for the employee)

- CIP requires ideas and knowledge from employees, who will only cooperate if they are guaranteed job security

- Simple key figures (comprehensible for employees) should be used to formulate targets and evaluate results

- Those involved must be aware that the current situation has weaknesses (quality, service, costs)

What is the procedure for introducing CIP?

Step 1: Preparatory measures

- Implementation of the 5S

- Creating standardized work instructions for all processes

- Visual representation of the current situation using display panels in production

- Introduction of a company suggestion scheme with incentives for the best ideas in order to address and sensitize employees across the board to the topic of improvements without pressure

Step 2: Pilot phase

- Start with smaller, voluntary “expert teams” that receive extensive training (social skills, PDCA, 7A…) and develop and implement several CIP pilot projects that are presented in the company

Step 3: Expansion to the company

- Training other employees (by department) in methodological and social skills

- Team members of the first expert team each lead a smaller CIP group

- Weekly CIP group meetings at which suggestions are discussed and tried out together in production

- Progress boards show the current group projects and results and serve on the one hand as direct feedback on good work (motivation) and on the other hand they encourage competition between groups

- Regular training and events (company rents a bowling alley every Tuesday, productivity party when a certain value is reached) to maintain the knowledge and motivation of employees in the long term

What problems are there in practice with CIP?

CIP is introduced in many companies and established in the short term. After a short time, however, increasing mobilization and motivation problems arise, which lead to a discontinuation. The main reason for this is the declining commitment of both management and employees. The reasons for this are

- Lack of backing/support from top management

- Lack of exchange of experience between CIP groups

- No structured and visible CIP approach in the company (no visual representation)

- Lack of target agreements

- Organizational changes that the CIP groups do not follow

- No continuation of regular method training

- No temporary leave for CIP measures (extra time for CIP)

- Lack of recognition for achievements

- Hierarchical organizational structures prevent “normal employees” from contributing their ideas

The implementation of Kamishibai is recommended in order to maintain CIP in the long term. Kamishibai contains all the elements of a location in the plant (island, line, warehouse) on a map, i.e. a brief description of all the key process steps there. The Kamishibai card is hung up directly on site. The manager must now audit the processes on the map every 2/4/8/12 weeks (depending on the design) and deal with the location himself and can thus initiate improvements. The results are presented in a management room for Kamishibai. Failure to complete and remove a card thus attracts attention in production and management. New cards are then distributed.

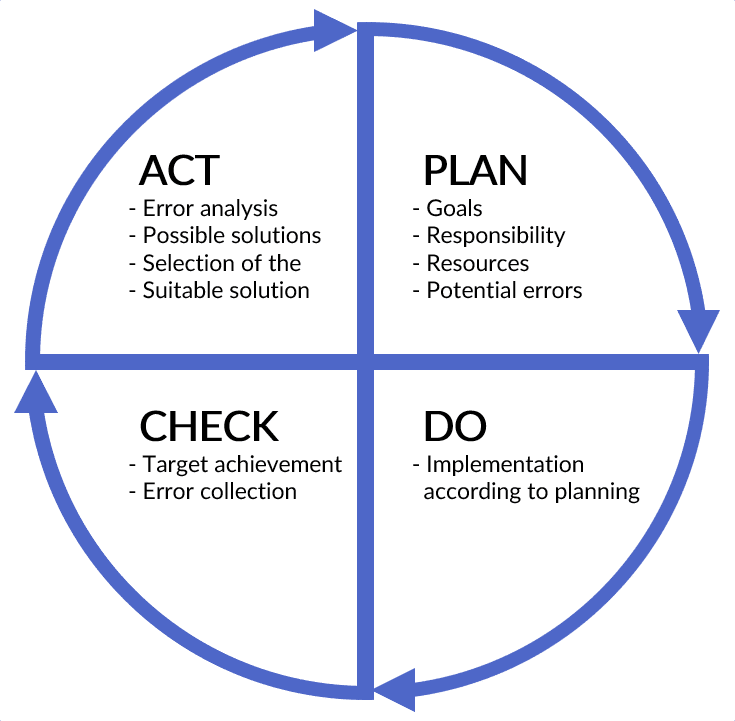

CIP with PDCA

A perceived problem can be systematically tackled and solved using the PDCA cycle (Deming wheel), eliminating waste. The procedure consists of four steps:

- Plan: Quantitative description of the initial situation First, the situation is described – if possible in data – and the obvious problems are identified. Based on the data, the target status and packages of measures are developed and agreed, i.e. who has to do what and by when.

- Do: The solution is implemented on a trial basis

- Check: After implementation, a target/actual comparison is carried out to check whether the new procedure is better than the previous one

- Act: The new procedure becomes generally binding